LED Warehouse Lighting

Efficient and Safe: Revolutionizing Industrial Warehouse Lighting with LED Solutions

ZGSM Lighting offers innovative solutions for industrial warehouse LED lighting, ensuring significant energy savings and eliminating maintenance concerns. Whether it’s a new construction project or the retrofitting of an existing space, our lighting solutions guarantee excellent lighting conditions, including uniform light distribution, high visibility, visual comfort, and glare-free illumination.

Lighting standards of warehouse lighting

ZGSM recommends designing warehouse lighting according to the lighting standard of EN12464-1. The standard has different requirements for racking, aisles and unloading areas. The following is relevant content of this standard.

Storage rack areas |

||||

Maintained illuminance Lux |

illuminance uniformity Uo |

Unified Glare Rating limit, UGRL |

Colour rendering indices (Ra) |

Specific requirements |

20 |

0.4 |

/ |

40 |

Illuminance at floor level. |

150 |

0.4 |

22 |

60 |

Illuminance at floor level. |

150 |

0.6 |

22 |

80 |

|

200 |

0.4 |

/ |

60 |

Vertical illuminance, portable |

According to Standard of EN 12464-1:2011 |

||||

Store rooms, cold stores |

|||||

Type of area, task or activity |

Maintained illuminance Lux |

illuminance uniformity Uo |

Unified Glare Rating limit, UGRL |

Colour rendering indices (Ra) |

Specific requirements |

Store and stockrooms |

100 |

0.4 |

25 |

60 |

200 lx if continuously occupied. |

Dispatch packing handling areas |

300 |

0.6 |

25 |

60 |

|

According to Standard of EN 12464-1:2011 |

|||||

Key factors to consider in warehouse Lighting

Illumination and uniformity

For warehouse lighting design simulation, lighting standards should be strictly followed, and corresponding calculation areas should be set for different areas in the warehouse to verify whether illumination and uniformity meet the requirements of EN12464-1.

High efficiency

Warehouse lighting should use high-efficiency LED lamps. With the advancement of LED technology, the luminous efficiency of lamps has gradually increased from less than 100lm/W in the past to 180lm/W or even higher. Therefore, only considering the power of lamps is no longer in line with the corresponding development trend. ZGSM recommends the use of high-efficiency LED industrial lighting fixtures to meet illumination requirements with lower power, which helps save energy and reduce electricity bills.

Lamp arrangement and anti-glare

In warehouse lighting, the arrangement of lamps needs to consider the location of the cargo stacking area, shelves, aisles and loading and unloading areas. After identifying these locations, plan the arrangement of lighting fixtures to avoid shelves blocking light and ensure adequate lighting in aisles and loading areas. At the same time, the anti-glare design of lamps should be considered to avoid disturbing the line of sight of workers.

Dimming

In warehouse lighting, dimming function is very necessary because the warehouse is not always in working condition. Common dimming methods such as microwave technology can make the lamps run at reduced power when no one is on the shelf or unloading area, and operate at 100% when there are people. Similarly, intelligent controls such as Dali dimming and Zigbee dimming can also be applied to warehouse lighting, although their cost is higher.

Choose ZGSM Lighting for Industrial Warehouse LED Lighting

Opting for efficient LED industrial lighting yields significant benefits. Lighting costs typically represent about 80% of total expenses in industrial warehouses. Monitoring and optimizing these expenses become crucial, and our LED solutions provide substantial savings while increasing productivity.

ZGSM has been committed to the development of high-efficiency factory lighting products, with the goal of saving energy. By using high-efficiency power supplies and LED lamp beads, we develop and produce lamps that provide excellent lighting effects to minimize energy consumption. In order to ensure that our lamps meet the relevant standards, we follow the EN12464-1 standard to carry out simulation tests to ensure that the required illuminance levels are provided in a given work area (including workshops, processing plants, warehouses and restrooms, etc.).

By combining the size of the work area, type of activity and task requirements, we are able to select the proper wattage and light output to meet lighting needs. These ensure that our products provide the correct lighting to increase productivity, while it also helps to reduce electricity costs.

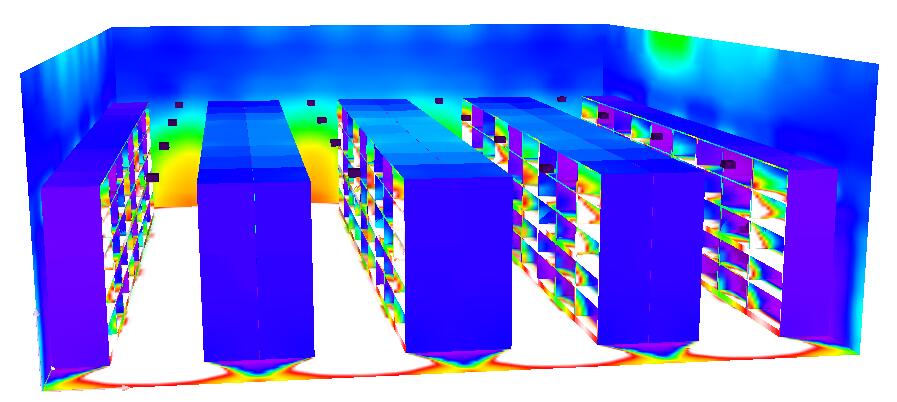

ZGSM can carry out lighting planning according to the characteristics of the warehouse (size, shelf position, aisles, etc.) and the customer’s lighting requirements. By rationally choosing the wattage and light distribution of the lamps, we can get the ideal lighting results. Combined with the use of dimming functions (such as microwaves), ZGSM’s high-efficiency factory lighting solutions can save a lot of energy for our customers. The following is ZGSM’s lighting design for the warehouse (including shelves). If you have a similar project that needs to be designed, please contact ZGSM and we will do our best to recommend a verified plan for you.

Industrial warehouses and logistics departments often face high energy consumption costs. By replacing traditional lighting with ZGSM Lighting’s modern LED technology, businesses can achieve up to 60% cost reduction and a rapid return on investment. We assess each customer’s specific needs and provide guidance on optimizing the lighting plan with our industrial interior solutions, maximizing energy savings.