Different light sources – LED vs incandescent fluorescent sodium and halogen

Taylor

Introduction

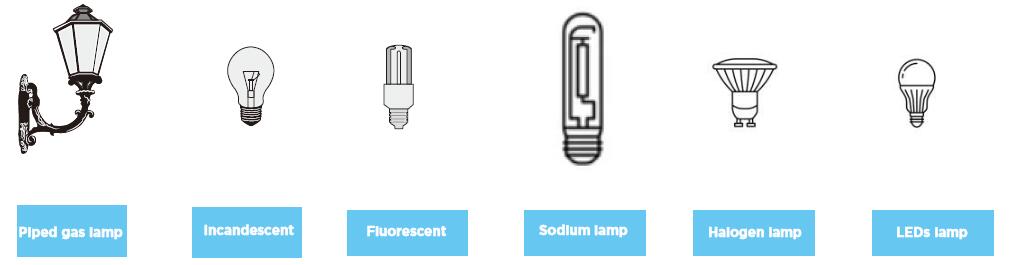

Since the use of street lights in 1879, the development of street lighting technology has experienced nearly 150 years of development. It has witnessed the evolution of different light sources from gas, to incandescent lamps, fluorescent lamps, to high-pressure sodium lamps, metal halide lamps, and even LEDs. Every application of these light source technologies has greatly promoted the development of street lighting technology, bringing a brighter, safer and energy-saving lighting environment to urban roads at night.

The history of piped coal gas street lights can be traced back to the late 18th century. Some areas of London, England began to use gas to illuminate streets. By 1879, Edison successfully installed carbon filaments into light bulbs, creating incandescent lamps, which were successfully used in street lights. In 1938, Iman invented the fluorescent lamp and began to replace incandescent lamps, but its application in street lights has been rarely reported. High-pressure sodium lamps were developed by General Electric Company and began to be widely used in street lighting in the 1960s. At that time, high-pressure sodium lamps were widely used in the field of street lighting and other lighting applications due to their advantages such as high luminous efficiency, low light decay, long life, low cost, and easy maintenance. Halogen lamps (also known as metal halide lamps) appeared after high-pressure sodium lamps. Compared with high-pressure sodium lamps, metal halide lamps have the advantages of optional correlative color temperature and good color rendering, so they have been used in street lighting to a certain extent. However, compared with high-pressure sodium lamps, its cost is higher, which limits its application in road lighting. On the contrary, it is used more in places that require higher lighting quality (such as stadiums, sports lighting and other commercial lighting).

Main parameters concerned in lighting technology

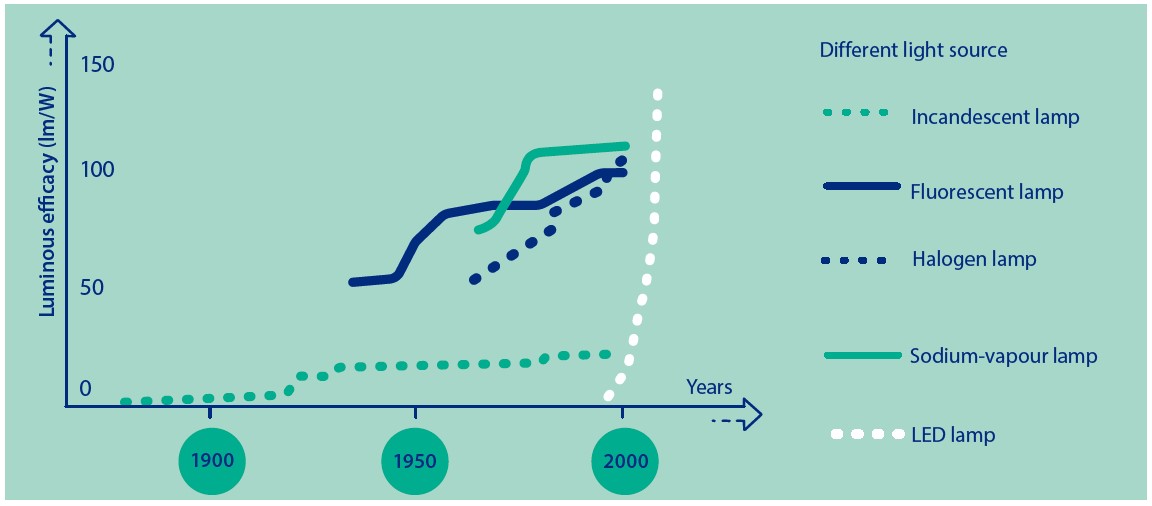

Light efficiency

The efficiency of the light source in converting electrical energy into visible light, that is, the luminous flux emitted by the light source for each watt of electrical energy consumed by the light source. So it’s expressed in lumens/watt or lm/W. A higher number indicates a more efficient light source. For example, a high-pressure sodium lamp consumes 100 watts of electrical energy and produces a luminous flux of 7,000 lumens, then light efficiency = luminous flux/wattage = 7000lm÷100W=70lm/w. Light efficiency is an important parameter for assessing the economic performance of a light source. It also produces a luminous flux of 7000lm, and LED lamps only need to consume 50W. This means that LEDs can save 50% of energy consumption to obtain the same lighting result, which helps reduce energy consumption and carbon emissions. This is very meaningful today when energy consumption and environmental protection are increasingly concerned.

Correlated color temperature

It’s expressed in absolute temperature K (Kelvin). When a standard black body is heated and the temperature rises to a certain temperature, the color of the light source begins to gradually change from red/light red/orange/white/blue to white/blue. Using the characteristics of this light color change, the light color of a certain light source is consistent with that of a black body. When the light colors presented at a certain temperature are the same, we call the absolute temperature of the black body at that time the correlated color temperature of the light source. The light color of low color temperature is warm (low proportion of blue, light color is yellowish), and the light color of high color temperature is cold color (high proportion of blue light, light color is white). Traditional light sources have lower color temperatures, such as 2800K for incandescent lamps and 2000K for high-pressure sodium lamps. Of course, the different color temperature of some lamps is available, such as metal halide lamps and LED lamps, but their range is usually between 1800-6500K.

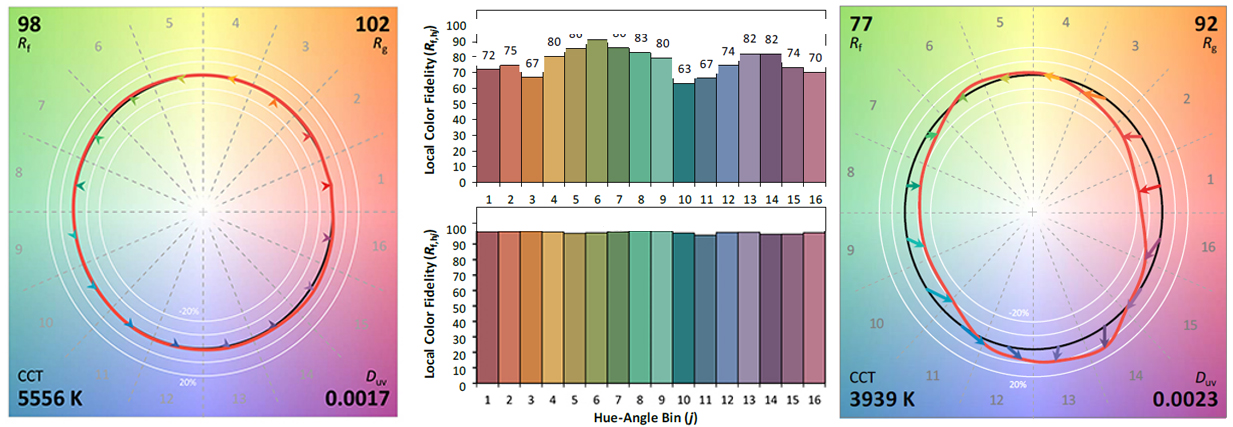

Color Rendering Index

Color Rendering Index (CRI or Ra for short) is an important indicator that describes the color rendering of a light source. It is a parameter that measures the ability of a light source to display the true color of an illuminated object, color rendering index Ra (0-100). CRI indicates the degree to which the color of an object under a light source matches the color of an object under a reference light source (usually sunlight or incandescent lamp). The higher the color rendering index, the closer the color of the illuminated object is to the color under natural light. Normally, we think that the display index of incandescent lamps is close to 100. This is because its light-emitting principle is to heat the filament to the incandescent state through current, thereby emitting a continuous spectrum of light, that is, this light contains various types of light in the visible range so it can better restore the color of objects. In the lab, we use a range of standard color samples (8-16) that represent different hues and saturations. The color performance of these samples under the test different light source (i.e., the light source to be evaluated) and the standard light source (such as daylight or incandescent lamp) will be observed and compared, and the evaluation will be made according to the ANSI/IES TM-30-18 standard.

Lifespan

The lifespan of a lamp usually refers to the time it can work normally under specified conditions of use. This definition covers the time from when a luminaire is turned on until its luminous flux decays to a specific proportion of the initial luminous flux (such as 70% or 50%). For example, ZGSM Rifle series street lamp L70>100000hrs @Ta 25℃, that is, when the ambient temperature is 25℃, the luminous flux of the street lamp can still be greater than 70% of the initial luminous flux after the lamp is lit for 100000hrs. However, these are theoretically calculated data, and the life span depends on many factors, including product design, lamp bead quality, and other influencing factors in the use environment. The theoretical calculation is based on the LM-80 test method, which tests LED chips for a long time (usually 6,000-17,000 hours) to measure their luminous flux attenuation and color temperature changes, and then combines some mathematical formulas to derive and evaluate their lifespan.

Light distribution

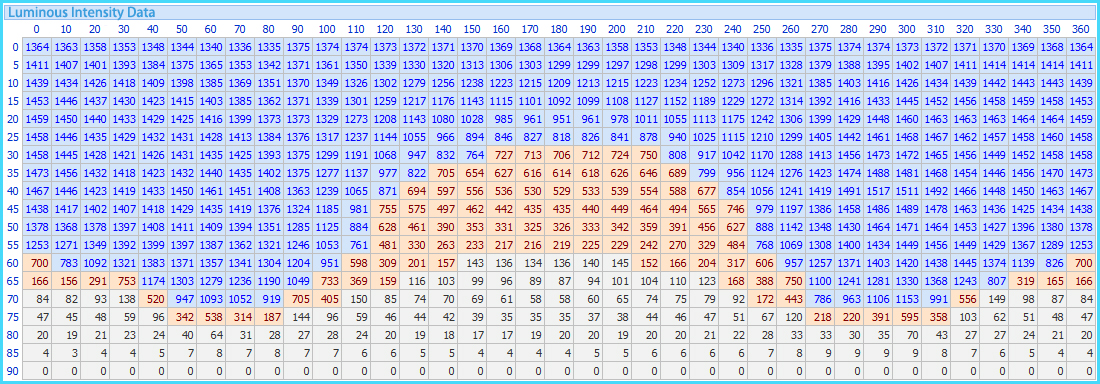

The light distribution of a lamp refers to the distribution of the luminous flux (light intensity) radiated by the lamp in different directions in the surrounding space, also known as the luminous intensity distribution. Light distribution is specified in terms of the luminous intensity in all directions in which a luminaire radiates its light, usually described in the C-gamma or C-γ coordinate system. ZGSM’s street lights usually use the C-γ coordinate system to test the light distribution of the lamps. In the C-γ coordinate system, the rotation axis of the C-plane is vertical and passes through the center of the luminaire (0-360 degrees). γ represents the direction on the vertical plane and ranges from 0 (downward) to 90 (horizontal) to 180 (upward). A photometric intensity meter is a numerical representation of the light distribution of a lamp. The following is a candela table(luminous intensity). With the light distribution (IES), we can import it into lighting calculation software to perform lighting simulation. Light distribution can also be classified according to its characteristics. A typical example is the IESNA light distribution classification method. Of course, you may be more familiar with Type IS, Type IIM, Type IIIL, and Type VS.

Different light sources and their characteristics

Incandescent lamp

An incandescent lamp is a thermal radiation light source that uses a tungsten filament to be in an incandescent state when current passes through it. It has the advantages of simple structure, low cost, good color rendering, and easy use, but its luminous efficiency is very low and its lifespan is short. Under normal circumstances, indoor and outdoor lighting no longer use incandescent lamps for general lighting, but instead turn to other light sources that are more energy-saving and longer-lasting. When used under special circumstances, its rated power should not exceed 100W. In addition, in order to improve their performance, halogen compounds such as iodine or bromine are used in the gas filling of incandescent lamps and the inner wall of the bulb. These halogen compounds redeposit volatile tungsten onto the filament, extending the life of the filament and making the bulb brighter and more efficient. Compared with incandescent lamps, tungsten halogen lamps have the characteristics of small size, long life, high light efficiency, good light color and stable light output, making them more widely used.

Fluorescent lamp

Fluorescent lamp is the most widely used and consumed gas discharge light source. It has the advantages of simple structure, high light efficiency, soft light emission and long service life. The luminous efficiency of fluorescent lamps is 4 to 5 times that of incandescent lamps, and its lifespan is 10 to 15 times that of incandescent lamps. It is an efficient and energy-saving light source. Fluorescent lamps can be divided into two categories: hot cathode and cold cathode according to their cathode working mode. The vast majority of fluorescent lamps for general lighting are hot cathode types. When they are energized, they heat the cathode through electron collision, resulting in the release of electrons, thereby producing fluorescence. Fluorescent lamps can be divided into double-ended fluorescent lamps and single-ended fluorescent lamps according to their appearance. Most double-ended fluorescent lamps are straight tubes with a lamp cap at each end (such as T12, T8 and T5). Single-ended fluorescent lamps have many shapes, such as H-shaped, U-shaped, double U-shaped, ring-shaped, spherical, spiral, etc., with the lamp cap at one end. Fluorescent lamps with a ballast and a standard lamp holder integrated into one are called self-ballasted fluorescent lamps. This kind of lamp cannot be disassembled without damaging its structure. According to the diameter of the lamp tube, fluorescent lamps include Φ38mm (T12), Φ26mm (T8) and Φ16mm (T5).

High-pressure sodium lamp

A high-pressure sodium lamp is a high-pressure sodium vapor discharge bulb that uses a discharge tube made of translucent polycrystalline alumina ceramic that is resistant to sodium corrosion. It emits golden-white light when working and has the advantages of high luminous efficiency (light efficiency up to 120~140lm/w), long life, and good fog penetration performance. It is widely used in roads, airports, docks, stations, parking lot, squares and industrial and mining enterprises illumination. Of course, it also has disadvantages, such as low color rendering index. Of course, there are ways to improve it, such as medium-color high-pressure sodium lamps and high-color high-pressure sodium lamps. Medium-color high-pressure sodium lamps and high-color high-pressure sodium lamps are based on ordinary high-pressure sodium lamps, appropriately increasing the sodium vapor pressure in the arc tube, thereby improving the color temperature of high-pressure sodium lamps and also the color rendering of the lamps. The correlated color temperature of medium-color high-pressure sodium lamps is 2200K, and the average color rendering index can be increased to 60, while the correlated color temperature of high-color high-pressure sodium lamps is 2500K, and the average color rendering index can be increased to 85.

Metal halide lamp(Halogen lamp)

Metal halide lamp is a gas discharge lamp that generates arc discharge and emits light in the mixed vapor of mercury and rare metal halide. It is a light source made by adding various metal halides to the high-pressure mercury lamp. The basic principle is to add a variety of metals into the arc tube of a high-pressure mercury lamp in the form of halides, so that these metal atoms ionize and emit light like mercury. The mercury arc discharge determines its electrical properties and heat loss, while the low-pressure metal halide filled in the lamp determines the luminous performance of the lamp. Metal halide lamps have the advantages of fluorescent lamps, high-pressure mercury lamps, and high-pressure sodium lamps, and overcome the shortcomings of these lamps. They have high luminous efficiency (65~140lm/W), long life (5000~20000h), and good color rendering (Ra is 65~95), compact structure, stable performance and other characteristics. By filling different metal halides, light sources with different characteristics can be made. Metal halide lamps can be divided into four categories according to the different filling materials: sodium thallium indium type, scandium sodium type, dysprosium holmium type, and tin halide type.

LEDs

LED lights, or light-emitting diodes, use solid semiconductor chips as luminescent materials. When a forward voltage is applied to both ends, electrons move from the N-type semiconductor (negatively charged) region to the P-type semiconductor (positively charged but lacking electrons) region. At the P-N junction, these electrons meet and recombine with holes (positively charged locations in P-type semiconductors). During this process, electrons jump from a high energy level to a low energy level, releasing energy in the form of photons, producing visible light. Light-emitting diodes were invented in the 1960s. At first, they only had red light, and then green and yellow light appeared. Their basic use is as an indicator light. It was not until the 1990s that blue-light LEDs were developed, and white-light L.EDs were soon synthesized and entered other lighting fields. After several years of development, LED has become very advantageous in terms of light efficiency, lifespan, color temperature, color rendering index, and light distribution.

Comparison of different light sources and the advantages of LED

Different light sources play an important role in modern lighting, each with its own unique characteristics and application scenarios. Incandescent lamps are popular because of their simple structure, low cost, and good color rendering (100). However, they also have shortcomings such as low luminous efficiency (10lm/W) and short life (1000hrs) that greatly limit its application, which also leads to It is gradually replaced by other light sources. As a highly efficient and energy-saving gas discharge light source, fluorescent lamps have the characteristics of relatively high luminous efficiency and long life. Its luminous efficiency can reach 50-80lm/w and its lifespan can reach 15,000hrs. It is widely used in various lighting places. High-pressure sodium lamps have more advantages in efficacy and lifespan than fluorescent lamps, so they are widely used in outdoor lighting such as street lamps. However, their low color temperature selection range also limits their application in other fields. Metal halide lamps combine the advantages of fluorescent lamps, high-pressure mercury lamps, and high-pressure sodium lamps. They have relatively high luminous efficiency (60-100lm/w), long life (10000-30000hrs), and good color rendering (up to 95). , which makes it very suitable for lighting applications that require relatively high color temperature and color rendering index, such as stadiums, parking lots (other large-scale lighting – docks) and commercial lighting areas (such as automotive headlights). LED has more advantages in color temperature, color rendering index, dimming flexibility, energy efficiency, service life and warm-up time, making it the best choice for modern lighting.

The following table compares the light efficiency, color temperature, color rendering index, lifespan and light distribution of different light sources.

| Light source | Luminaire efficiency | CCT | CRI | Lifetime | Light distribution |

| Incandescent | <10lm/w | 2800K | 100 | 1000hrs | N/A |

| Fluorescent | 50-80lm/w | different CCT are available | 80-85 | 15000hrs | N/A |

| High-pressure Sodium | 70-120lm/w | 2000-2500K | 20-25 | 30000hrs | N/A |

| Halogen | 60-110lm/w | different CCT are available | 60-95 | 10000-30000hrs | N/A |

| LED | 130-190lm/w | different CCT are available | 70-90 | 100000hrs | Asymmetric and symmetric |

Through comparison we can draw the following conclusions: Incandescent vs LED: The color is more natural and the light is soft, but the disadvantage is also obvious, that is, the lifespan and light efficiency can no longer meet the needs of modern lighting.

Fluorescent vs LED: Fluorescent is widely used in the early stage, and it is relatively easy to replace and maintain fluorescent lamps without the need for large-scale modifications. The initial cost is low, and it is currently used in household and commercial lighting. It is inferior to LED in terms of light efficiency, lifespan, and light distribution.

Sodium vs LED: Sodium had many advantages in outdoor places such as street lights and square lighting since 1970s. However, it has obvious disadvantages in color render index, light efficiency(no efficiency as LEDs anymore), lifespan, light distribution, etc., and is no longer suitable for lighting in street lights, squares, parks and other places. Whether the entire lamp is replaced by LED or the light source is replaced by retrofit LED, compared with the initial cost and later benefits, it is very suitable to use LED lamps to replace sodium lamps.

Halogen vs LED: The luminous efficiency of halogen lamps is not higher than that of sodium lamps, but its advantages in color temperature and color render index make it widely used in other stage lights, sports lights and car lights(heatlights). With the emergence of LED technology, its advantages in light efficiency, correlated color temperature, display index (almost), lifespan and light distribution have greatly limited the application of halogen lamps in the above fields.

ZGSM LED lighting solution

Since 2005, the company has been focusing on various lighting projects. Our LED products include street lights, floodlights, stadium lights, industrial lights, ceiling lights, etc. In these lighting fields, ZGSM's products have always pursued features such as high luminous efficiency, long life, reasonable light distribution, high color rendering index, and optional color temperature. Our products are backed by full certifications and reporting. In addition, we also provide lighting simulation and customized lighting solutions. If you are interested, you can contact us for more information or click on the product link below.

Summary

With the development of technology, LED has gradually become the protagonist in the field of lighting. This is because it has its advantages(compare to other different light sources) in light efficiency, color temperature, color rendering index, lifetime and light distribution. Incandescent lamp, as the earliest light source, has basically withdrawn from the stage of lighting history due to its disadvantage in light efficiency and life. Fluorescent lamps are mainly used for household or commercial lighting, and are less used in outdoor lighting. Although high-pressure sodium lamps and metal halide lamps have made certain progress in light efficiency and life, they do not have the advantage of LED. Even if the price is low or the color rendering index is high (metal halide lights), in recent years, the stadium lighting and car lighting are gradually replaced by LED. On the contrary, through relevant learning, we can find that leds have certain advantages in light efficiency, color temperature, color rendering index, light distribution and easy control. The comprehensive performance of LED in all aspects are excellent other traditional light sources, which makes LED more widely used in the field of lighting, becoming the main force of outdoor lighting and industrial lighting.

FAQ

Related Posts

Guide for canopy light with battery backup

Tags:

Author

Taylor

Sales Engineer

I am Taylor, with 10 years of experience in lighting sales. Throughout my career, I have developed a deep understanding of the lighting industry and its products. My expertise lies in building strong relationships with clients, understanding their needs, and providing tailored lighting solutions that align with their requirements.