Quality Control Measures Undertaken by LED Street Light Manufacturers Before Delivery

William Yu

Introduction

In this article, we will introduce in detail the quality control of LED lamps produced by ZGSM-Street Light Manufacturers in each link before leaving the factory. From the incoming inspection of PCB boards, to the production and quality inspection of the shell, to the incoming inspection of sheet metal parts, packaging materials and joint connectors, as well as the inspection of patch quality, power supply installation, optics and structure, and finally Sampling random testing and handling of non-conforming products, as well as packaging and shipping. Every link is strictly checked to ensure product quality. Our goal is to let readers understand ZGSM’s quality control methods in the process of producing LED lamps, and how we ensure the performance and reliability of our products. By reading this article, you will be able to know our products better and have a comprehensive understanding of our quality control system.

Examination of material

LED light source incoming material inspection

LED light sources are often an important part of lighting products. Incoming material inspection can include inspection of LED packaging, appearance, size, luminous flux brightness, forward voltage, CCT and CRI to ensure that its quality and performance meet the requirements. Street light manufacturers-ZGSM conducts quality inspection of LED chips in accordance with relevant specifications. For details, please refer to the document.

PCB board incoming inspection

PCB board is one of the key components in electronic products. ZGSM’s inspection of PCB incoming materials includes inspection of size, thickness, line connection, pad quality, etc., to ensure that its quality and reliability meet the requirements. See the documentation for details.

Lamp housing production and quality inspection

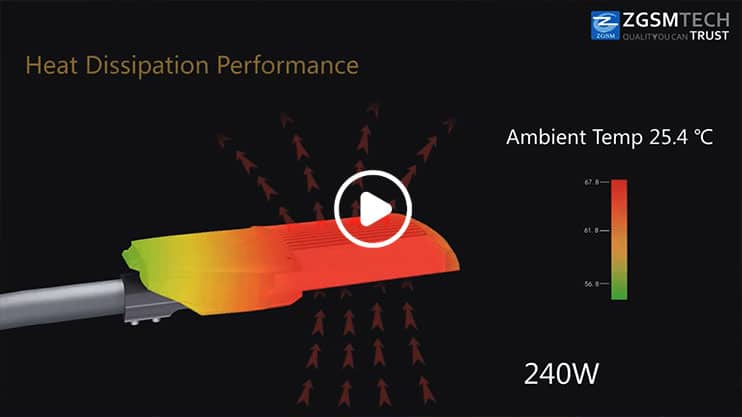

The lamp housing is a part used to protect the light source and electrical components. Production and quality inspections can include inspections of the exterior, dimensions, surface treatment, and structural integrity of the housing material to ensure that its manufacturing process and quality meet requirements. ZGSM’s luminaire enclosures follow the following quality control specifications, see the document for details.

- We choose ADC 12 aluminum ingot with high strength, good mobility and more corrosion resistance, and put it into the furnace to 600℃ to get aluminum water, and put it into the specially designed mold to apply a pressure of 2500 tons, so that it becomes firm, better impact resistance and heat conduction.

- Each die-cast hair embryo must undergo preliminary quality inspection, with defects such as cold insulation defects, bulge, dark damage and other defective products will be returned to the furnace for casting.

- After passing the preliminary quality inspection, it must be through 15-20 days of stacking to eliminate the die casting stress of the product, and subsequent processing in the die casting side with timeliness treatment.

- After 15 days of stacking, first use a corner grinder to remove the thimble and burr, and then use sandblasting to remove the residual foreign bodies on the surface.

- After the surface treatment, electrophoresis and spray treatment as required to meet the requirements of corrosion resistance and aesthetics.

- After delivery to the assembly workshop, the following warehousing quality inspection shall be carried out again:

Sheet metal parts incoming material inspection

Sheet metal parts are usually used for supporting structures of lamps, such as ZGSM street lamp adapters and floodlight brackets. Incoming material inspection can include inspecting the size, surface treatment, welding quality and other aspects of sheet metal parts to ensure that their quality and precision meet the requirements, see the document for details.

Inspection of packaging materials

Packaging materials play an important role in the protection and presentation of products. The inspection may include the inspection of the size, strength, surface printing quality, moisture resistance and other aspects of the packaging material to ensure that its quality and reliability meet the requirements of product packaging, see the document for details.

Material supply inspection for the joint connector

Connectors are components used to connect circuits in electronic products. ZGSM commonly used connectors include PG connectors and terminal blocks (such Wago connectors). Material supply inspection may include inspection of the physical properties and chemical composition of the materials used in the connector to ensure that its quality and reliability meet product requirements. For details, refer to the document.

Fastener material inspection

Fasteners are used to fix and connect various components, such as screws, washers, and clips. Material inspection may include inspection of fastener material type, strength, corrosion resistance, etc., to ensure that its quality and reliability meet product requirements, see documents for details.

SMT Process by Street Light Manufacturers

With the help of surface mount technology, we have realized the automatic production of LED module, and we have obtained the LED module with high reliability, low defect rate of solder joints and high cost performance. Our company’s SMT process mainly includes below 4 steps.ZGSM is a professional street light manufacturers in China.

- Preparation of SNT process, including import of process file data, install the materials (PCB, LEDs).

- Screen Printer to apply solder paste on PCB board.

- SMT P&P Machine to put LEDs on PCB Board.

- Reflow Oven for reflow soldering chips on PCB board.

- Quality inspection for LED module. Multimeter, visual inspection, visual inspection whether the LED positioning is in the designated area, whether smooth, no leakage welding and LED damage, lamp bead surface pollution-free, no light source after power on, LED heat conduction surface and aluminum substrate seamless.

Street Light Assembly by Manufacturers

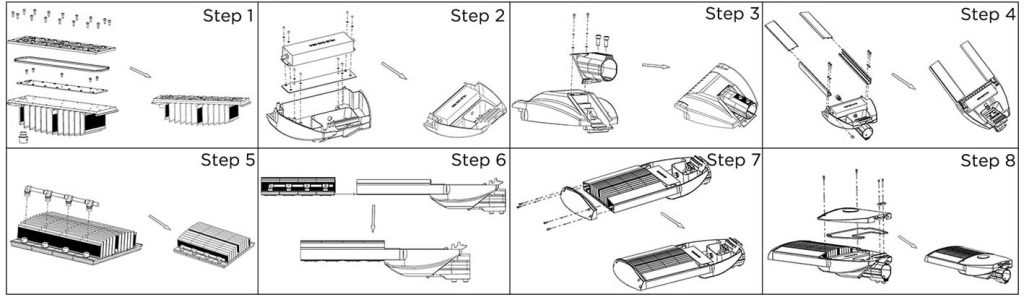

The assembly of LED lamps is different for different products. Let us take the modular street lamp as an example to briefly describe the assembly process:

Preparations: Gather all the components and materials needed for assembly, including LED modules, housings, heat sinks, drivers, wires, lenses, and connectors, etc.

Install the LED module: Install the LED module obtained by the SMT process on the radiator according to the requirements, install optical components such as lenses, reflectors or diffusers on the LED module, and complete the wiring for standby.

Install the shell: After the shell has passed the quality inspection, use specific screws or brackets to complete the fixation, install the required components (including surge, connectors, connectors and fixing plates, etc.), at this step we need to install the set LED driver in the shell.

Wiring and Connections: Use appropriate wires and connectors to connect the LED module with the LED driver, according to the instruction document

Make sure the correct electrical connections are made. Install the remaining components to ensure the integrity of the luminaire (including mounting brackets, etc.), and seal the housing to ensure waterproof performance.

Lighting Fixture Quality Inspection

Once the luminaire has been assembled, a quality control check is required to ensure the integrity and functionality of the assembled modular street light. This may include visual inspections, electrical testing and performance evaluations, among others.

Visual inspection (all lighting fixture): A visual inspection is performed to check for any visible defects or abnormalities in street lighting fixtures. This includes checking the overall structure, finish and alignment of components.

Electrical testing (all lighting fixture): Electrical testing is performed to verify the electrical performance of street lighting. This may involve measuring parameters such as voltage, current, power consumption and electrical connectivity to ensure compliance with safety and efficiency standards.

Photometric testing (random): Photometric testing is performed to evaluate the light distribution and intensity of street lighting fixtures. This includes measuring parameters such as luminous flux, luminous intensity, color temperature and color rendering index (CRI), lighting distribution, etc. These measurements help evaluate lighting performance and compliance with lighting design requirements.

Environmental testing (random): Street lighting fixtures are often subjected to environmental testing to assess their durability and performance under different conditions. This may include testing its water resistance (IP rating), dust resistance, temperature resistance and shock resistance.

Impact and Mechanical Testing (random): Impact and mechanical testing is performed on street lighting fixtures to assess their structural integrity and ability to resist external forces. This ensures that it will survive typical environmental and operating conditions without damage.

Aging and reliability testing (all lighting fixture): Street lighting fixtures may undergo accelerated aging testing to assess their long-term reliability. This involves simulating prolonged use and monitoring the performance and degradation of the device over time.

Packaging and Delivery

Size and structure: The packaging design should be designed according to the size and shape of the LED lamps. The lining materials include customized pearl cotton, partitions or other packaging materials to fix the position of the lamps and prevent them from moving during transportation.

Carton: LED luminaires are usually packaged to ensure protection during shipping and handling. LED lamps will be placed in strong cardboard boxes to prevent damage. If possible, the packaged lamps can be placed in boxes with sufficient cushioning materials for reinforcement to prevent lamps from being damaged during violent transportation.

Documentation: Packaging often includes product documentation such as user manuals, installation instructions, warranty information, and certificates of conformity. These materials provide important information about LED luminaires and their proper use.

Delivery: LED luminaires can be delivered by various shipping methods, such as land, air or courier services. The packing material can be adjusted according to the shipping method. During shipping, LED luminaires should be handled with care to avoid any potential damage. We will include a fragile label or handling instructions on the packaging to remind handlers of the fragility of the contents.

At the same time, we will monitor the transportation progress of LED lamps, inform customers in real time, and prepare corresponding materials for customer clearance. Through these means, customers can successfully complete customs clearance as soon as the package arrives.

Summary

Street light manufacturers undergo rigorous steps to ensure quality and performance. First, they conduct design and development to meet project requirements. Throughout production, they inspect and control the quality of raw materials such as LED chips, circuit boards, heat sinks, and power supplies. Suppliers’ credibility is verified, and quality management systems and standards are followed. Street light manufacturers are committed to delivering reliable, high-quality, and safety-compliant LED products. Stringent quality control measures guarantee product excellence and dependable performance.

During production, LED street lights undergo various manufacturing and assembly stages. This includes installing LED modules, connecting circuit boards, and fitting power supplies and housings. Testing and quality control play a vital role throughout this process. LED street lamps are thoroughly tested for luminous flux, efficacy, color temperature, spectrum, and safety compliance, ensuring adherence to standards and specifications. Once manufactured, street light manufacturers carefully package and mark the products to prevent transportation damage and provide essential information. The LED street lights are then transported through logistics channels and ultimately delivered to customers.

As a reputable LED street light manufacturers, we prioritize the utmost quality and customer satisfaction. We are dedicated to ensuring the highest standards in our products, giving you peace of mind when choosing ZGSM street lamp products. Rest assured, we prioritize your rights and interests as our valued customer. Purchase ZGSM street lamps with confidence, knowing that your needs are our top priority.

These steps and control measures ensure that LED street lights go through a strict production and quality management process before being delivered to customers to meet customer needs and expectations. As a street light manufacturers, ZGSM has been committed to providing high-quality LED products (street lights, factory lights, flood lights, etc.) to provide reliable lighting solutions and good user experience. Get in touch with us to get more details.

Related Posts

Discussion on SPD for street light and its warranty

Ultimate Guide to Typical Solar Powered Street Lights

Smart Street Light System Create Smart City Lighting

Author

William Yu

Sales Engineer

Hi. I’m Willian Yu. I have been working in the sales department of ZGSM company for 13 years, specializing in street lighting projects. My expertise includes lighting simulation, project design, and certification consulting.